Product Categories

- All

- Air Cooled Heat Exchangers

- Air-to-Air Heat Exchangers

- Indirect Heat Exchangers for Solids

- Cooling Towers

- Direct Fired Heaters

- Electric Heaters

- Electric Heating Elements

- Finned Tube Coils

- Hairpin, Double Pipe Heat Exchangers

- Heat Exchanger Service and Parts

- Heat Recovery

- Indirect Fired Recirculating Gas Heaters

- Industrial Duty Electric, Steam and Glycol Heaters

- Mist Eliminators

- Pipeline Heating Systems

- Plate Coil Sections and Assemblies

- Plate & Frame Heat Exchangers

- Scrubbers and Thermal Oxidizers

- Shell and Coil Heat Exchangers

- Shell and Tube Heat Exchangers

- Spiral Heat Exchangers

- Thermal Fluid Systems

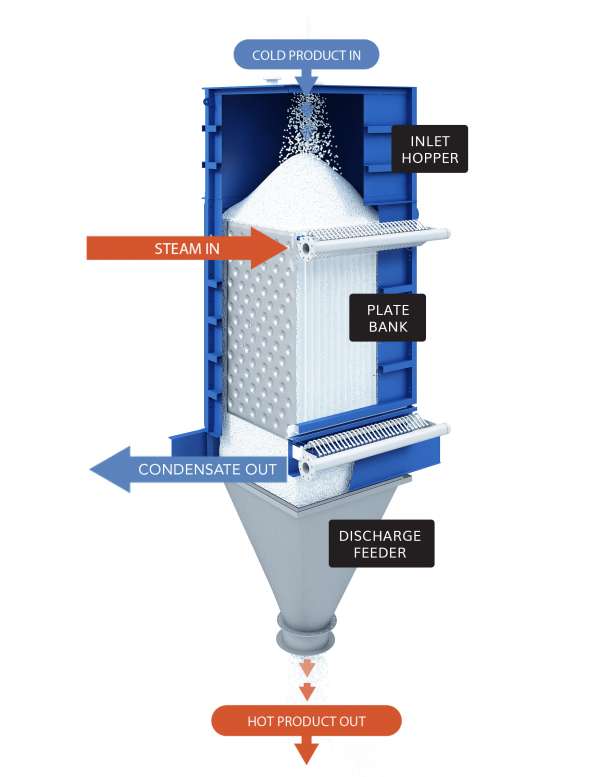

Indirect Heat Exchangers for Solids

Ultra-efficient bulk solids heating

Solex's heat exchangers heat bulk solids to uniform temperatures of up to 700°C while using up to 90% less energy, virtually no emissions and a significantly smaller installation footprint than traditional methods.

Waste heat from elsewhere in the facility can be captured and reused, improving efficiency and generating even greater cost savings.

And thanks to a vertically oriented modular design with no moving parts, you can quickly increase capacity and eliminate bottlenecks while reducing maintenance costs at the same time.

Cool bulk solids with 90% greater efficiency

Our heat exchanger technology is capable of cooling bulk solids from up to 2,000°C indirectly by conduction, consuming up to 90% less energy. It’s engineered to handle substantial thermal stresses without cracking or damage, while offering guaranteed thermal performance for a superior end product.

Waste heat can be recovered and used elsewhere in the facility. No air is ever in contact with the product, virtually eliminating emissions, fines, bacterial and odor contamination.

A vertically oriented modular design uses little floor space and is easily expandable should capacity requirements increase.